Plastic Injection Mold Design – Detailed Course Comparison

| Course Details | Foundation | Mastery |

|---|---|---|

| Official Name | Foundation Mold Designing | Mastery Mold Designing |

| Duration | 2 – 2.5 Months | 4 – 5 Months |

| Weekly Schedule | 3 – 4 Classes | 4 – 5 Classes |

| Mode | Hybrid (Live + Recorded) | Hybrid (Live + Recorded) |

| Software | Unigraphics NX | Unigraphics NX |

| Molds Covered | 10 – 12 Designs | 18 – 20 Designs |

| Internship | No | Available |

| Placement | Yes | Yes |

| Brochure | Download PDF | Download PDF |

Mr. Ramesh Sharma is the owner of RSTOOLS INDIA Moulding Industry and a passionate teacher of mould design. He focuses on practical, hands-on training that links software skills to real industrial work. His approach helps students understand concepts clearly and become confident, job-ready mould design engineers.

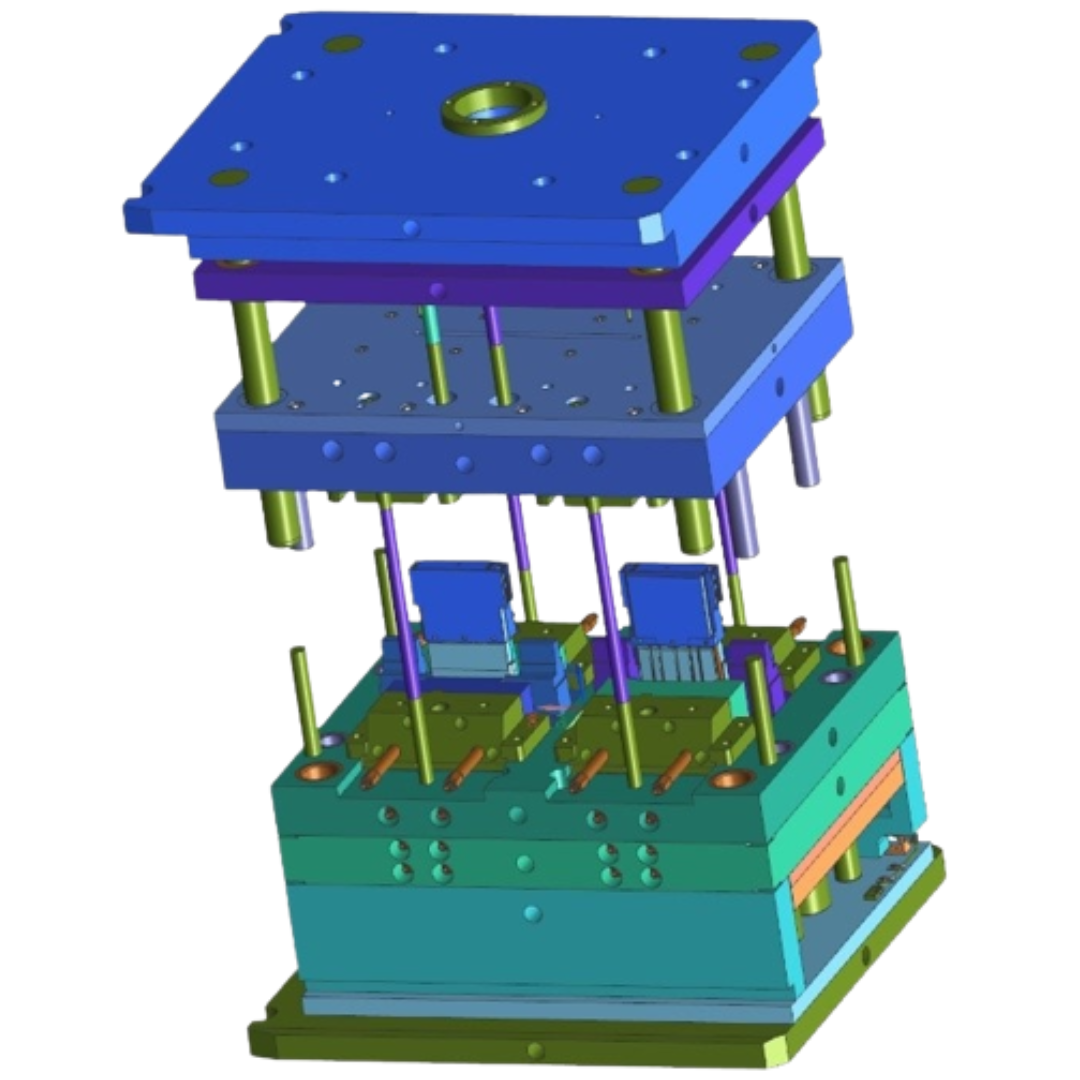

This course covers complete plastic injection mould design concepts, mould types, parting lines, and Automobile mold Designs. Students learn mould components, design calculations, and real mould case studies used in manufacturing industries. The training focuses on practical mould design skills, concept understanding, and job-oriented learning.

Enter your details below to get the full course syllabus and pricing.

Everything you need to know about our Plastic Injection Mold Design training and career breakdown.