At our facility, we've incorporated one advanced VMC Machine BFW Agni 45+. This machine boasts a varying bed size of 800*600*500, ensuring versatility in precision machining. Operating at an RPM of 10K, our VMCs utilize a 0.5mm cutter diameter, a key component in achieving meticulous machining results. Not only do these machines efficiently meet the demand for greater accuracy, but they also exemplify total reliability, offering cost-effective solutions to our clients.

We've just added a CNC EDM with a moving table and fixed column. This upgrade boosts our process efficiency, refining surface finishes on molds, and elevating accuracy in their creation. The machine excels in threading and drilling through tough materials. Its orbital machinery feature is a standout, allowing us to achieve intricate undercut profiles, significantly enhancing the value throughout our entire manufacturing process.

At our workshop, we've introduced cutting-edge Milling Machines featuring advanced DRO technology from the esteemed USA Kent Company. Operating at an impressive 16K RPM, these machines utilize a 0.5mm cutter diameter for attaining precise results. They epitomize unwavering reliability, providing our clients with efficient and budget-friendly solutions.

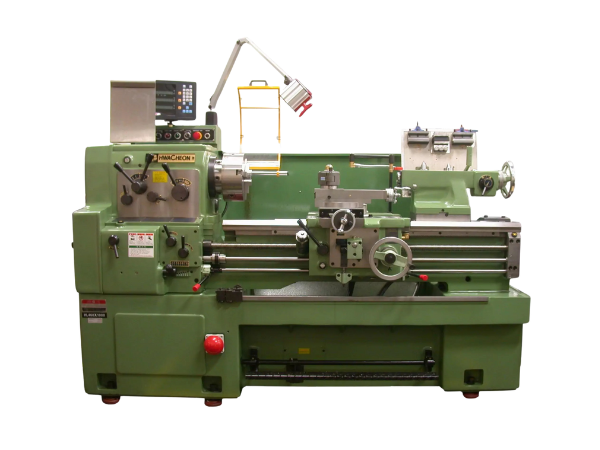

RSTools has one Lathe Machine with DRO boasting a diameter and length capacity of 200 mm. These machines specialize in machining profile punches for dies and molds. With the help of Digital Read Out (DRO) technology, we gain extra accuracy for our customers, ensuring every component meets exact specifications.