At RSTOOLS INDIA PRIVATE LIMITED, we specialize in the design and manufacturing of custom jigs and fixtures that are critical to achieving precision, repeatability, and efficiency in your manufacturing processes. Since 2002, under the leadership of Mr. Ramesh Sharma, we have been instrumental in helping industries across India streamline their operations, reduce human error, and improve product quality.

Jigs and fixtures are more than just tools; they are the backbone of consistent production. They hold workpieces accurately, guide cutting tools, and ensure every part is identical to the last. Our deep understanding of machining, assembly, and inspection processes allows us to engineer solutions that directly translate into improved productivity and reduced operational costs for your facility.

We offer a comprehensive range of design and manufacturing services for various types of jigs and fixtures:

To ensure Google recognizes our expertise, here's a detailed look at how we approach each project:

We start by thoroughly analyzing your product's design, manufacturing process, and specific requirements. This includes understanding the machining operations, assembly sequence, and inspection criteria. Our goal is to identify bottlenecks and areas where a jig or fixture can significantly improve efficiency.

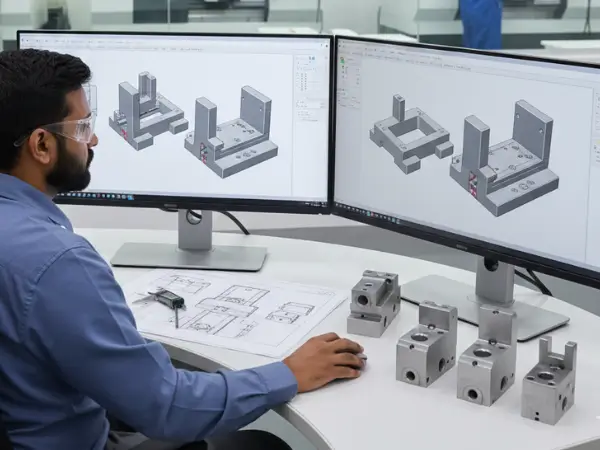

Using industry-leading software like Unigraphics (UG) NX, CATIA, and SolidWorks, our engineers develop precise 3D models of the jigs and fixtures. This allows for virtual prototyping, interference checking, and optimization before any physical manufacturing begins. We focus on: * Ergonomics: Ensuring the fixture is easy and safe for operators to use. * Clamping Mechanisms: Designing efficient and secure clamping to prevent workpiece movement. * Loading/Unloading Efficiency: Minimizing the time required to load and unload parts.

We select the most appropriate materials (e.g., hardened steel, aluminum, specialized alloys) based on the application, wear resistance, and cost-effectiveness. For critical fixtures, we perform FEA (Finite Element Analysis) to simulate stresses and ensure structural integrity under operational loads.

Once the design is finalized and approved, the jigs and fixtures are manufactured in our state-of-the-art facility using precision CNC machining. Every component undergoes rigorous quality control checks to ensure it meets the design specifications and tolerances.

We don't just deliver; we ensure seamless integration into your production line. Our team can provide on-site assistance for commissioning, operator training, and ongoing technical support.

Our custom jigs and fixtures are vital tools across a wide array of sectors: