At RSTOOLS INDIA PRIVATE LIMITED, we are leaders in the design and engineering of high-performance sheet metal dies. Since our establishment in 2002 by Mr. Ramesh Sharma, we have been the trusted partner for manufacturers needing robust, accurate, and long-lasting tooling for metal stamping and forming. From single stage dies to complex progressive tooling, we engineer solutions that ensure efficiency, precision, and repeatability in your metal fabrication processes.

In today's fast-paced manufacturing world, a poorly designed die leads to costly material waste, premature tool wear, and inconsistent part quality. Our expertise is rooted in two decades of hands-on experience, allowing us to anticipate and eliminate these issues during the design phase. We deliver dies that are optimized for high-volume production, minimizing downtime and maximizing your return on investment.

We offer a full spectrum of die design solutions tailored to meet diverse industrial demands:

Google and advanced users expect transparency and detail. Our rigorous design process leverages cutting-edge technology to ensure superior performance:

We begin by thoroughly analyzing the part geometry and material specifications (e.g., steel, aluminum, copper). We conduct Formability Studies using CAE software to predict how the metal will behave during stamping, identifying potential issues like thinning, wrinkling, or tearing before design begins.

For progressive dies, we meticulously plan the strip layout, optimizing material utilization to minimize scrap. Each station of the die is strategically planned for specific operations, ensuring smooth material flow and precise part progression.

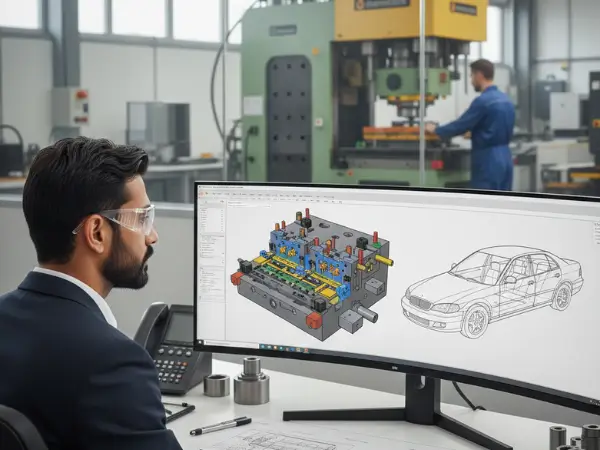

Using industry-leading software such as Unigraphics (UG) NX, CATIA, and SolidWorks, we create detailed 3D models of the entire die assembly. This includes: * Punch and Die Inserts: Designed for precise cutting and forming. * Guide Pillars and Bushings: Ensuring accurate alignment and smooth operation. * Stripper Plates and Pressure Pads: Essential for material control and part ejection. * Sensor Integration: Designing for in-die sensing to prevent errors and ensure continuous operation.

Sheet metal naturally "springs back" after forming. Our engineers incorporate springback compensation into the die design and use advanced simulation to predict and correct for this phenomenon, ensuring final part accuracy.

We provide a comprehensive package that includes detailed 2D manufacturing drawings, Bill of Materials (BOM), and assembly instructions, ready for your tool room.

Our precision sheet metal die designs empower a diverse range of critical industries: